Common Challenges with Risers

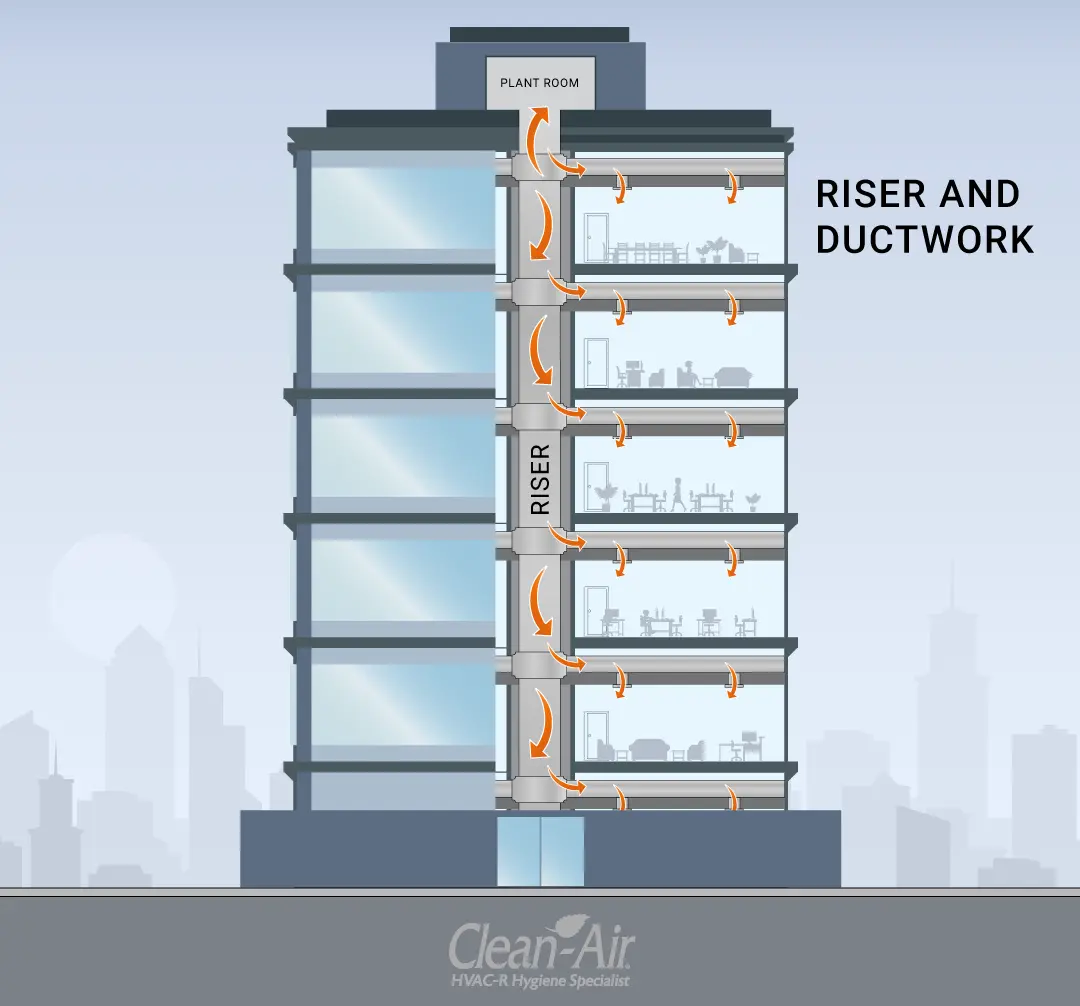

Accessing and maintaining HVAC Risers can be challenging due to their central placement within a building or attachment to an outer wall. Typically spanning multiple stories, HVAC risers are crucial for multi-story buildings and high-rise structures, enabling centralised control of climate systems and ensuring consistent indoor air quality and temperature.

An HVAC riser is a vertical shaft or conduit that runs between floors in a building, connecting the central plant room to various levels. It carries air, chilled or hot water, or refrigerant, allowing the HVAC system to distribute heating, cooling, and ventilation throughout multi-story buildings.

Types of HVAC Risers:

- Ventilation Risers: Carry air to different floors for ventilation and temperature control.

- Exhaust Risers: Distribute exhaust air from bathrooms, kitchens, or industrial spaces to the building's exterior.

- Riser Pipes: Used to transport water to and from cooling equipment.

Riser cleaning refers to the maintenance and cleaning of a building's vertical utility shafts or risers. Extract Risers, in particular, are notoriously difficult to access, inspect, and maintain due to their positioning—either running through the centre of a building or bolted onto an exterior wall. Their height and required roof access further complicate maintenance.

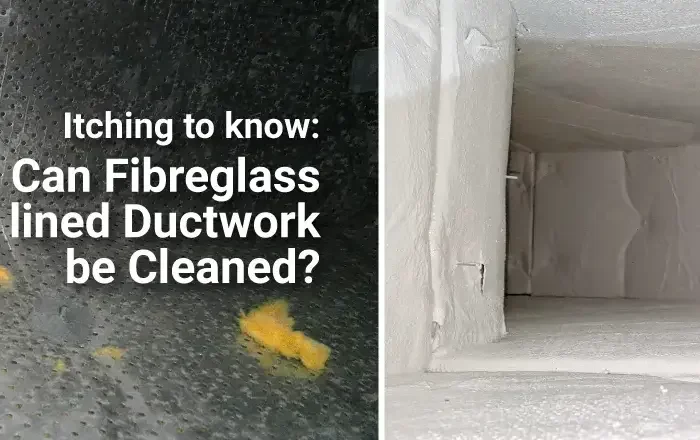

ABOVE Inspection findings: Fibreglass and building debris in the base of the supply air riser, serving the ground floor. Credit: Clean-Air Photo Archive

LEFT Fibreglass in ground floor supply air duct. RIGHT Damaged insulation throughout supply air riser. Credit: Clean-Air Photo Archive

Neglecting riser cleaning can lead to severe consequences, including:

- Blockages due to accumulated debris such as dust, dirt, and building materials. (See image below: Clogged riser with debris)

- Hygiene issues, as damp or dirty conditions can promote microbial growth.

- Fire hazards resulting from combustible buildup.

- Potential non-compliance with building regulations or insurance policies, leading to fines or required remedial work.

ABOVE HVAC riser, visual and camera inspection, with rope access. BELOW Manual Antimicrobial Coating. Credit: Clean-Air Photo Archive

Solutions to Cleaning and Maintaining Risers

Proper maintenance and cleaning of risers require specialised techniques and equipment:

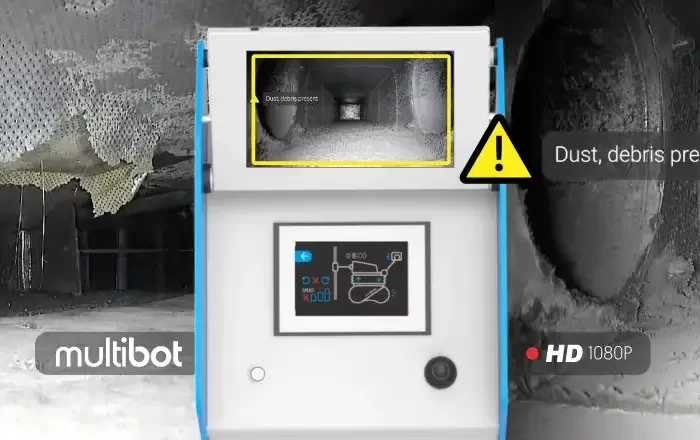

✅ Robotic Equipment – Advanced robotic inspection and cleaning devices allow for thorough assessments and maintenance in hard-to-reach areas.

✅ Far-Reaching Equipment – Telescopic and extendable tools help technicians clean risers efficiently without full physical entry.

✅ Rope Access Technicians – IRATA-certified professionals use climbing equipment to access and maintain risers safely.

✅ Debris Removal and Cleaning – Specialised suction and filtration systems remove blockages and improve airflow efficiency.

✅ Insulation Encapsulation or Replacement – Protects risers from external damage and ensures insulation remains effective.

✅ Antimicrobial Coatings – Application of antimicrobial treatments prevents bacterial growth and improves air quality.

By implementing these solutions, property managers and building owners can ensure that HVAC risers remain clear, compliant, and efficient, contributing to a healthier indoor environment.

VIDEO The antimicrobial coating of a vertical duct riser using an airless sprayer with a rotary attachment and inspection camera. The setup is lowered into the riser via a pulley system, allowing for full 360-degree coverage of hard-to-access ductwork.

Overall, maintaining HVAC risers is a critical aspect in ensuring optimal building functionality and indoor air quality. From ventilation to exhaust and water transport, these systems play a pivotal role in multi-story buildings. Neglecting riser cleaning can lead to various issues, including blockages, hygiene concerns, fire hazards, and regulatory non-compliance.

To safeguard your property and enhance indoor air quality, trust Clean-Air's expertise in riser cleaning and antimicrobial coating. With specialist equipment and extensive experience, we offer tailored solutions to keep your risers clear, compliant, and efficient. Contact us today at Clean-Air to discuss how we can assist you in maintaining a healthy indoor environment. Get in touch here

![]()

Related: Can Fibreglass-lined Ductwork be Cleaned?

Over time, factors like air turbulence, fluctuating temperatures, and humidity can degrade the fibreglass lining.

Related: Multibot Makes Duct Inspections Faster, Safer...

With Multibot, fewer access points need to be cut into the ductwork, as it can travel over 20 meters through multiple sections with ease.