Our recent study carried out in a hospital demonstrated a key factor of for understanding the science behind the product and why it's so important to know this when determining the right solution for the job.

Effective performance of UV-C is all about the level of energy fields it generates

ABOVE Mould growing on AHU: the result of low quality UV-C means mould and bacteria continue to grow on cooling coils and other surfaces inside the AHU. These contaminants then release harmful mycotoxins into the airstream.

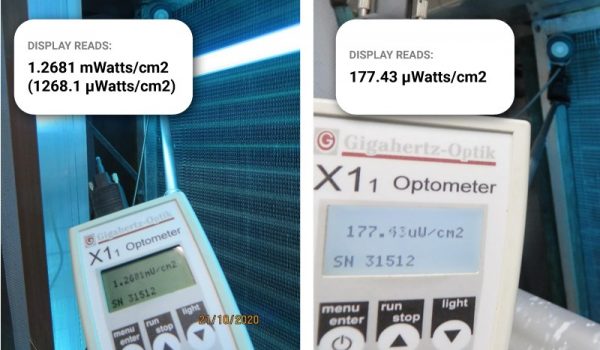

We found the existing UV-C install fell 7 times below the Clean-Air UV-C output rate

After examination of the hardware, output measurements diagnosed the root cause of the problem, concluding that the existing equipment installed did not meet minimum output requirements to be effective in this setting.

RIGHT The competitor's existing UV-C: Installations fall short of the necessary science based minimum output on the coil face. 7 times below the Clean-Air UV-C. Based on the competitor’s literature, stating they lose 20% output over 2-Years; if these lamps are near the 2 years (LED lights indicate they are good) then they would have only 220 μWatts/cm2 when new, still 5.6 times below our UV-C.

When UV-C is running correctly it leads to coil pressure reduction, airflow improvement, cooling coil heat transfer improvement and AHU cooling capacity gains

After remediation and install of Clean-Air UV-C we measured 4 key elements:

1. Cooling Coil Pressure Drop Reduction of 6.1% (Pre: 99.51 Pa / Post: 93.37 Pa)

A reduction in the pressure drop across the cooling coil indicates less restriction. Less restriction through the cooling coil fins means Bio-film is being removed resulting in better heat transfer and improved airflow. Better heat transfer equates to more efficient removal of heat from the air and therefore means less volume of chilled water required to achieve the same space condition.

2. Airflow Improvement of 5.5% (Pre: 57697 m3/h / Post: 61080 m3/h)

An increase in airflow is a result of removing the Bio-film that blocks the space between the cooling coil fins. With less restriction more air volume can pass through the coil to be delivered to the occupied space.

3. Chilled Water Coil (CHW) Delta T’s (ΔT) Improvement (Heat Transfer Efficiency) of 14% (Pre: 6.50 Deg C ΔT / Post: 7.41 Deg C ΔT )

An increase in the chilled water entering and leaving temperature difference (ΔT) indicates that the coil is operating more efficiently. With Bio-film removed the chilled water pumped through the cooling coil is absorbing more heat from the air as it passes over the clean cooling fins. Better heat transfer means less volume of chilled water required to achieve the same space conditions or the ability to raise the Chilled Water Supply temperature without affecting space conditions.

4. AHU Cooling Capacity Gain of 57kW (Pre: 231,242W / Post: 288,921W )

Cooling capacity gain is derived from measuring the energy difference or Total Heat removed at the cooling coil before and after installation of Clean-Air UV-C Emitters by measuring the air entering and leaving wet bulb temperatures, we can calculate the heat in and heat out with the difference being the Total Heat removed (Cooling Capacity). With Bio-film removed the chilled water pumped through the cooling coil is absorbing more heat from the air as it passes over the clean cooling fins.

In summary, correct scoping and installation of UV-C meeting a required level of output affords; higher performance, increased energy efficiency, reduced cleaning costs and a lower risk of airborne infection. This case is a real world example of quality vs. price and where premium UV-C doesn't cost, it pays.

Enjoying the read? Learn more about UV-C here at cleanairaust.com.au/uvc, or have our team run you through their expert insights from the full report, just email the team sales@cleanairaust.com.au, we’re always on hand to offer specialist solutions and detailed analysis of your HVAC-R Systems.